- Home

- Plastic Recycling Solution

- Plastic Bottle Recycling

Plastic Bottle Recycling

With decades of experience in cleaning and recycling PET polyester bottles, CRSTA can customize various washing solutions, recycling plans and site plans according to customer’s different requirements.

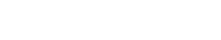

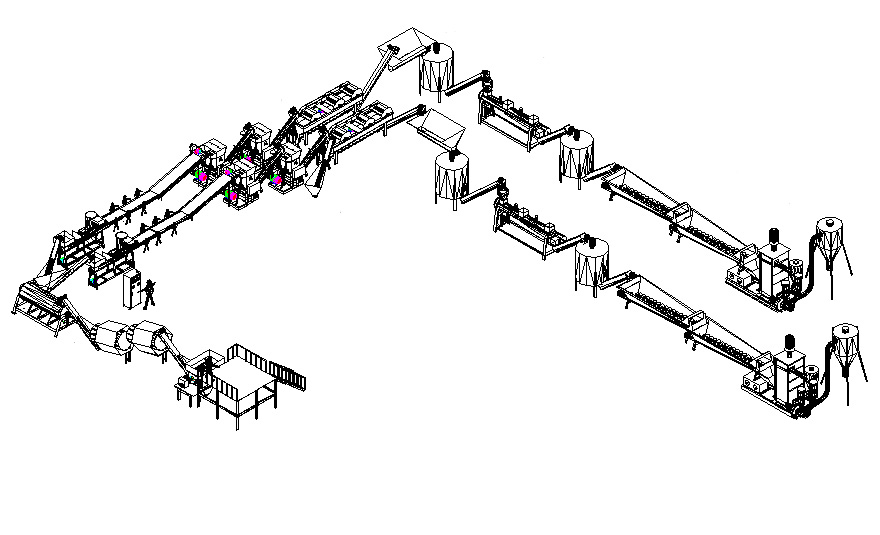

The plastic bottle recycling solution is suitable for the turnkey processing line including delabeling, crushing, cleaning, drying and packaging of waste PET bottles like mineral water bottles, Coke bottles, etc. Featured by low energy consumption and high output, this production line greatly improves the production efficiency, and meets top-level cleaning requirements.

PET bottle bale breaker——Screw conveyor——Trommel screen——Cool pre-washer——Screw conveyor——Hot pre-washer——Screw conveyor——Delabeler——Sorting table——Conveyor——Crusher——Screw conveyor——Crusher——Friction washer——Floating washing tank——Screw conveyor——Buffer screw conveyor——Hot washer——Screw conveyor——Friction washer——Screw conveyor——Buffer tank——Screw conveyor——Dual screw wash tank——Dryer——Storage hopper

Sorting conveyor——Belt conveyor——Automatic crusher——=Strong friction washer——Spray washer——Spray washer——Sink float tank——Screw conveyor——Horizontal centrifugal dryer——Electric dryer——Air conveyor——Separator——Quantitative feeding machine——Rubber and plastic separator——Loader——Baling

About us

Founded in 2004, CRSTA Machinery can provide not only various recycling equipment, but also customized plastic recycling solutions for customers.

Originated from a waste plastic washing factory, we have accumulated from the 11-year development a wealth of experience and professional knowledge of plastic processing.

In 2015, CRSTA officially entered the field of manufacturing recycling equipment, especially plastic recycling equipment.

We have more than 50 employees, 8 of which are experienced research staffs who can design the most suitable plastic recycling solutions for customers based on customers’ requirements and their rich experience in equipment manufacturing.